Federal Guidelines for Airport & Port Construction

Airport & Port Federal Guidelines- General Contractors Need to Know - the Human Factor

Did you know that federal guidelines call for more than castings rated for Extra Heavy-Duty Loads?

Every informed contractor knows that airport and port construction must conform to a seemingly endless list of federal and state regulations and guidelines. They are already familiar with the AASHTO and ASTM requirements for iron hatch covers for airport underground utilities — they must be rated for aircraft wheel loads.

Pretty simple, right? But before you choose your next hatch, do you know that federal guidelines call for more than castings rated for Extra Heavy-Duty Loads?

Federal Guidelines

Manufacturers today must do more than pass AASHTO’s extra heavy-duty load testing protocol and FAA’s bolt assembly requirements.

The FAA also requires:

“ease of maintenance” for worker access;

And the FAA further states that:

“…human factor considerations should be addressed during the early stages of design and development.”

For the General Contractor (GC), this means that underground access hatches must now be easy to operate for maintenance technicians. And here’s why you can rely on the design details of the Airport Extra Heavy-Duty Series — offering three sizes with the Hinged Hatch with Dual Lift Assembly.

The “Human Factor” means that underground access hatches must meet FAA required ergonomics — or ease of operation — for the underground utility technician. Compared to EJ, hatch manufacturers offering an exposed spring assist assembly have not paid sufficient attention to FAA’s “ease of maintenance” mandate. Why you may ask? Just look at the product details.

The “Human Factor” means that underground access hatches must meet FAA required ergonomics — or ease of operation — for the underground utility technician. Compared to EJ, hatch manufacturers offering an exposed spring assist assembly have not paid sufficient attention to FAA’s “ease of maintenance” mandate. Why you may ask? Just look at the product details.

The critical details

EJ pays attention to the critical details that maximize ergonomics — the ease, functionality and safety of the worker.

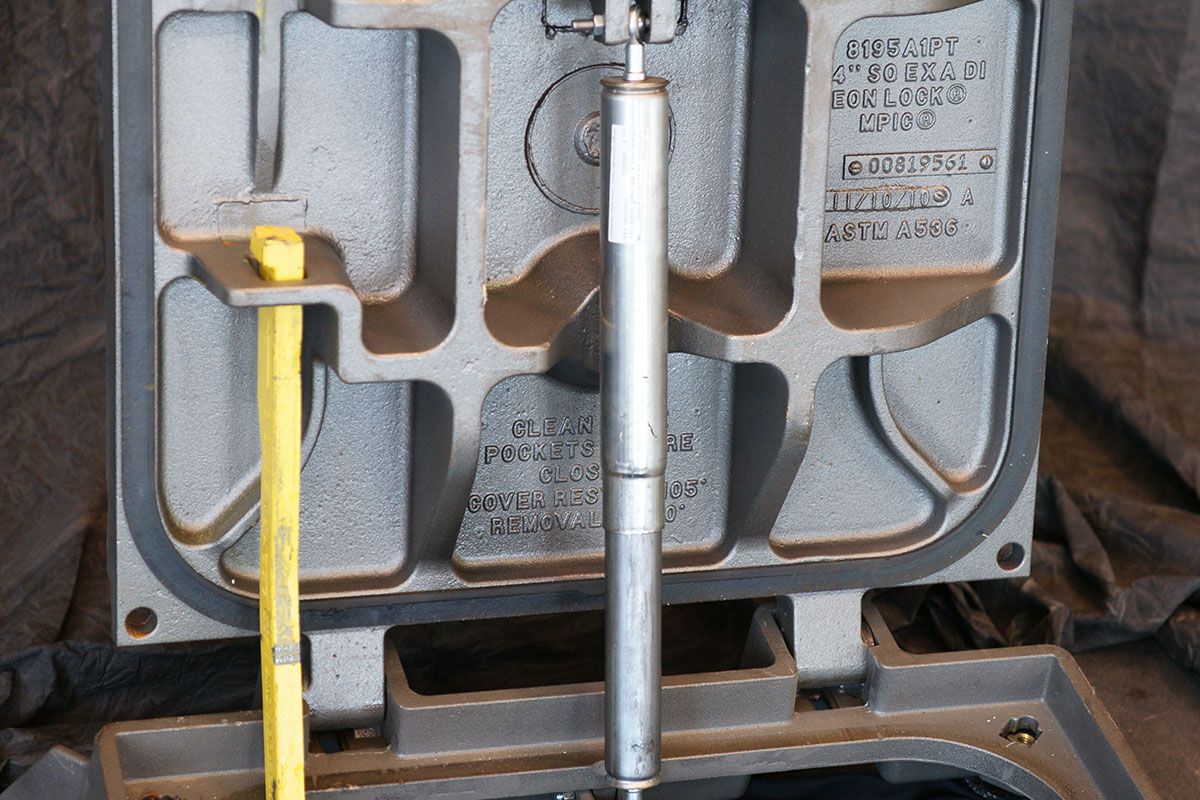

The Lift Assist by EJ is a corrosion-resistant stainless steel mechanical spring strut with a rugged design that is maintenance free.

Mechanical strut takes up less space in the worker’s clear opening than a traditional spring assist.

In simple terms, an EJ utility hatch means that the airport’s telecommunication technician can easily lift and close a 550-pound iron lid with just 35 lbs. of arm force — across the full range (105°) of motion.

“Ease of maintenance” — the “Human Factor” — is precisely why the informed GC recognizes the benefits of the Hinged Hatch with Dual Lift Assembly by EJ. EJ offers superior ergonomics over the competition:

- A technically advanced mechanical lift assembly with a patented self-engaging safety bar - are superior features to other hatch manufacturers.

- Ergonomically engineered hatch assemblies guarantee the minimum opening effort and strain for the airport maintenance worker.

The designers at EJ have the best reputation in the industry for optimizing every detail of the final product, ensuring compliance with federal guidelines for ease of use and airport access security. For construction of today’s high-tech airport and port facilities, contractors depend on EJ as the leader in the design, manufacture and distribution of the most innovative infrastructure access solutions. EJ has a proven track record for delivering the highest product reliability and mechanical efficiency available.

The designers at EJ have the best reputation in the industry for optimizing every detail of the final product, ensuring compliance with federal guidelines for ease of use and airport access security. For construction of today’s high-tech airport and port facilities, contractors depend on EJ as the leader in the design, manufacture and distribution of the most innovative infrastructure access solutions. EJ has a proven track record for delivering the highest product reliability and mechanical efficiency available.

As a GC, you understand that time is money. The last thing you need is a compliance violation delaying the jobsite schedule. So, when choosing underground access hatches that are engineered to meet the latest federal guidelines — including the “Human Factor” — you can rely on optimized design details for the best solutions available by EJ today.

Learn More

Talk to an expert at EJ to find out how the innovative solutions by EJ can work for your next project. Contact us today or schedule a Lunch and Learn.