Forming Skirts

Forming Skirts- The EJ Innovation That Became an Industry Standard

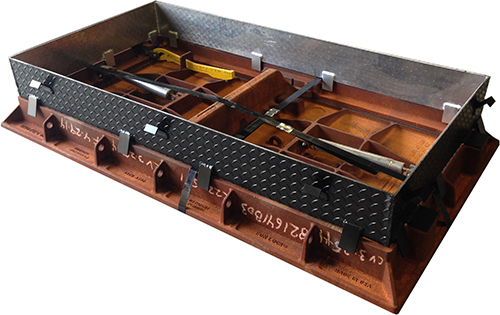

CUSTOM FABRICATED, LEAVE-IN-PLACE FORMING SKIRTS FOR DUCTILE IRON & ALUMINUM HATCHES CREATE A FRAME HEIGHT THAT MATCHES ANY CONCRETE TOP SLAB THICKNESS.

In 1984, Kistner Concrete Sales Engineer Clarence Conrad called EJ Facilities Manager Tim McKernan and said, "I've got a problem."

"Kistner was the first precaster that EJ worked with directly when we started manufacturing access hatches," McKernan explains. "And our hatches weren't the problem; Clarence was frustrated by a part of the precasting process that came up every time hatches of any kind were cast into concrete vaults."

Conrad explained that hatches are usually set into concrete structures of greater thickness than the hatch—for example, a hatch with a total thickness of 3.5" would be set into an 8" thick concrete slab. To keep hatches flush with the final surface and to keep openings clear, precasters had to build solid forms to support the hatch during pours. In the above example, a 4.5" frame would have to be built to match the hatch dimensions, and it had to be sturdy enough to stay in place during the concrete pour. This worked, but it created several problems:

- Making and attaching the frame was tedious and labor-intensive, so costs per pour were high.

- After the pour, stripping the forms was also labor-intensive, raising costs even more.

- The best form material Kistner had discovered was styrofoam wrapped with cellophane. This was lightweight, and the cellophane sped up form stripping, but a lot of waste was generated and this raised disposal costs. Cellophane was also bad aesthetically; it left an unattractive concrete surface that wasn't up to Kistner standards.

A NEW SOLUTION BECOMES AN INDUSTRY STANDARD

After listening to Conrad's explanation, and reviewing the precasting process, McKernan proposed an elegant solution- access hatches would be extended by lightweight aluminum "skirts", so that their total thickness would match that of the proposed slab. This proved to be a winning solution with several advantages over the old process:

After listening to Conrad's explanation, and reviewing the precasting process, McKernan proposed an elegant solution- access hatches would be extended by lightweight aluminum "skirts", so that their total thickness would match that of the proposed slab. This proved to be a winning solution with several advantages over the old process:

- It was easy to customize hatches as needed for different slab thicknesses.

- Precasters didn't have to build new forms for each pour, and since the skirts stay in place after the pour, form stripping was also eliminated. This greatly reduced labor costs, and sped up production.

- The aluminum skirts are reinforced by, and become part of, the precast concrete structure—the entire hatch opening is covered with a metal surface that is durable and good looking.

Now this simple, innovative idea has become a precast industry standard. "Really they work for anyone, even contractors working on site," McKernan says. "But precasters tend to value it more than others, so this is mainly for them." Conrad agrees; "The skirts are efficient, cost-effective, and make for a higher quality product—they're a great innovation."

Many manufacturers now provide similar forming skirts, but McKernan likes to point out that EJ still makes a better product; "Everyone has copied this, but we invented it. And most of the copiers have just a few limited heights—we're more flexible and can do anything, so custom thicknesses for particular vaults or structures are not a problem."

Many manufacturers now provide similar forming skirts, but McKernan likes to point out that EJ still makes a better product; "Everyone has copied this, but we invented it. And most of the copiers have just a few limited heights—we're more flexible and can do anything, so custom thicknesses for particular vaults or structures are not a problem."

"The skirts are efficient, cost-effective, and make for a higher quality product—they're a great innovation."

Clarence Conrad, Sales Engineer at Kistner Concrete

More recently, EJ has extended the forming skirt idea to their line of ductile iron hatches with a modified version of the skirt that can be set in place within a slab form. The heavy iron hatches are then set securely in the skirt, which supports them during a pour without the need for suspension by a crane or gantry. It's another way EJ speeds up precasting and lowers costs for manufacturers.

"We weren't thinking about patents back then," McKernan says. "But that little idea really caught on, and I'm glad. It's made life easier for an important infrastructure industry."

Learn More

Talk to an expert at EJ to find out how the innovative solutions by EJ can work for your next project. Contact us today or schedule a Lunch and Learn.