Load Ratings for Cast Iron Products

Choose the correct load rating for your infrastructure project.

Load Ratings

Load rating is defined as the range of force a cover (or grate) and frame can withstand before failing. It indicates the effectiveness of street infrastructure and has been adopted by State DOTs, municipalities, and private developers across the United States.

All products manufactured by EJ are designed to meet or exceed the specified loading requirements and conform to AASHTO and ASTM standards. These standards specify material quality and load requirements.

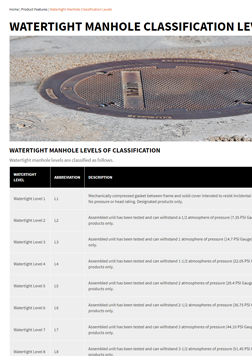

Descriptions of the six rating classifications are below.

| Load Rating | Minimum Proof Load (lb) | Description |

|---|---|---|

| Non-Traffic | Under 2,500 | Castings are intended for use in areas that are not subject to vehicle traffic. Generally nothing over 2,500 lb. should be placed on these items. Duty rating is 0 - 2,500 lb. |

| Light Duty | 2,500 | Casting may be able to withstand some loading but should not be placed in traffic. Castings must proof load test to a minimum of 2,500 lbf. Castings with test results that range between 2,500 lbf. and 16,000 lbf. fall within the light duty classification. An example of this type of product is meter boxes. Usually, meter boxes are placed in grassy areas and are run over by lawn mowers although they often end up in driveways and parking lots. |

| Medium Duty | 16,000 | 16,000 pounds is the H-20 design loading criteria. These castings can accept traditional loading, but do not have the most up to date safety factor. Castings must proof load test to a minimum of 16,000 lbf. Castings with test results that range from 16,000 lbf. and 40,000 lbf. fall within the medium duty classification. Many castings with medium duty designation have been safely used in traffic areas for years. |

| Heavy Duty (H20) | 40,000 | Castings must proof load test to a minimum of the AASHTO M306 H20 requirement. Castings with test results that range between 40,0000 lbf. and 100,000 lbf. fall within the heavy duty classification. All EJ designed heavy duty castings meet these criteria. This loading designation is appropriate for traditional traffic loading. |

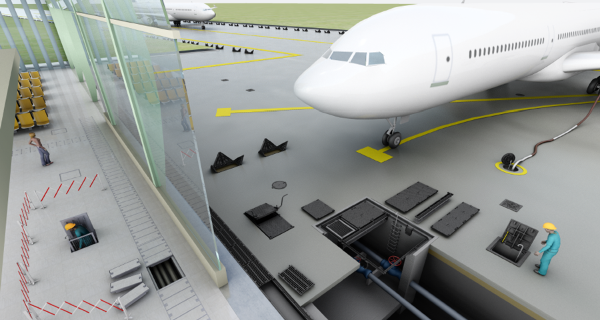

| Extra Heavy Duty | 100,000 | Castings that are designed as extra heavy duty must proof load test to a minimum of 100,000 lbf. This meets the design load associated with the FAA wheel loading. Castings with test results that range between 100,000 lbf. and 200,000 lbf. fall within the EJ classification extra heavy duty. |

| Extra Heavy Duty Airport | 200,000 | Castings able to accept a minimum proof load of 200,000 lbf. This includes an additional safety factor over FAA design loading. |

Material Selection

Depending on the model, our construction castings can be manufactured using either gray iron or ductile iron.

Gray iron has an unequaled record of success as a material for construction castings. Gray iron is highly resistant to corrosion and maintains compressive strength, abrasion resistance, vibration absorption, and low-notch sensitivity. Additionally, gray iron has a long service life and is very cost effective. Ductile iron combines the advantages of gray iron with greater strength, toughness, higher impact resistance and increased durability without additional weight. Because it has the ability to withstand greater loads without failure, it is often specified for extra-heavy load applications.

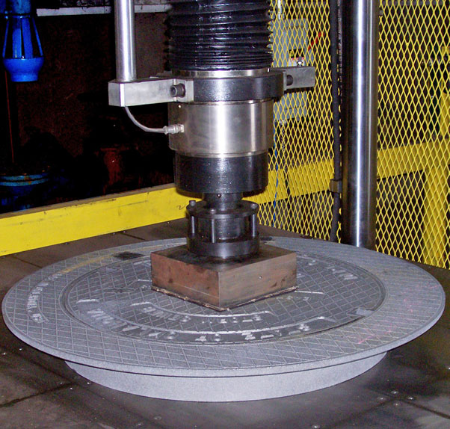

Proof Load Testing

All proof load testing is done per an AASHTO M 306-10 test setup. Proof load is applied to a 9" x 9" plate in the center of the center of the cover. After passing a proof load test, all castings are carefully inspected. Cracks or permanent deformation are cause for rejection. Frequently, EJ castings are tested far beyond the specified proof load, often to destruction. Contact your EJ Sales Representative if you have custom or specific loading criteria.

Learn More

Your EJ sales representative can assist you in choosing the right product for specific load ratings for your next project. Contact us today or schedule a Lunch and Learn.