Innovation on the Airside

Airports - With safety in mind, engineers and customers realize the benefits of our access solutions

With safety minded engineering and innovation, EJ provides reliable customer driven solutions in airports and ports around the world

La información se presenta en Inglés. Una vez traducida, está se actualizará.

La información se presenta en Inglés. Una vez traducida, está se actualizará.

Modern airports employ cutting-edge technology to track and guide thousands of airplanes around the globe, and serve the millions of passengers within them. However, this sophisticated technology relies upon traditional infrastructure to safely bring electricity, water, and fuel to airports and remove the byproducts of their operations.

Years of Expertise

"Listening to the clients who are specifying and installing these products requires visiting their sites, seeing how they operate, and understanding the details." -Lee Veldboom

EJ has been producing practical solutions to infrastructure systems for ports and airports throughout the world for decades.

One such recent project was for the Aeroporto Lisboa in Lisbon, Portugal. On this project EJ provided the 8197 single door and double door hinged hatch product along with our popular ERMATIC modular access system. The ERMATIC product is a modular hatch solution allowing designers to cover large vaults with infinite length and up to a 17’ width.

“Quality was important to the client,” recalled Lee Veldboom, P.E., Technical Engineering Manager and project leader, who specializes in the airports and ports segment at EJ. “We had good communication with our Lisbon client, and we were able to produce the right products for this environment. These included ductile iron aircraft-rated access hatches.”

For airports and ports that are looking for solutions to meet excessive loading environments, products need to be appropriately designed, tested and certified. The products that EJ supplies to its customers must function in all client-specified environments for decades into the future.

Providing the right solution

“Listening to the clients who are specifying and installing these products requires visiting their sites, seeing how they operate, and understanding the details.” explained Veldboom. “We take this information from the field and return it to our engineering staff in product development. We can then design and recommend the proper product.”

“Our products are designed to meet and exceed Federal Aviation Administration load bearing requirements.” Veldboom added. “Many of our new products are designed with lift assist, so that airport and port personnel can easily and safely access their infrastructure.”

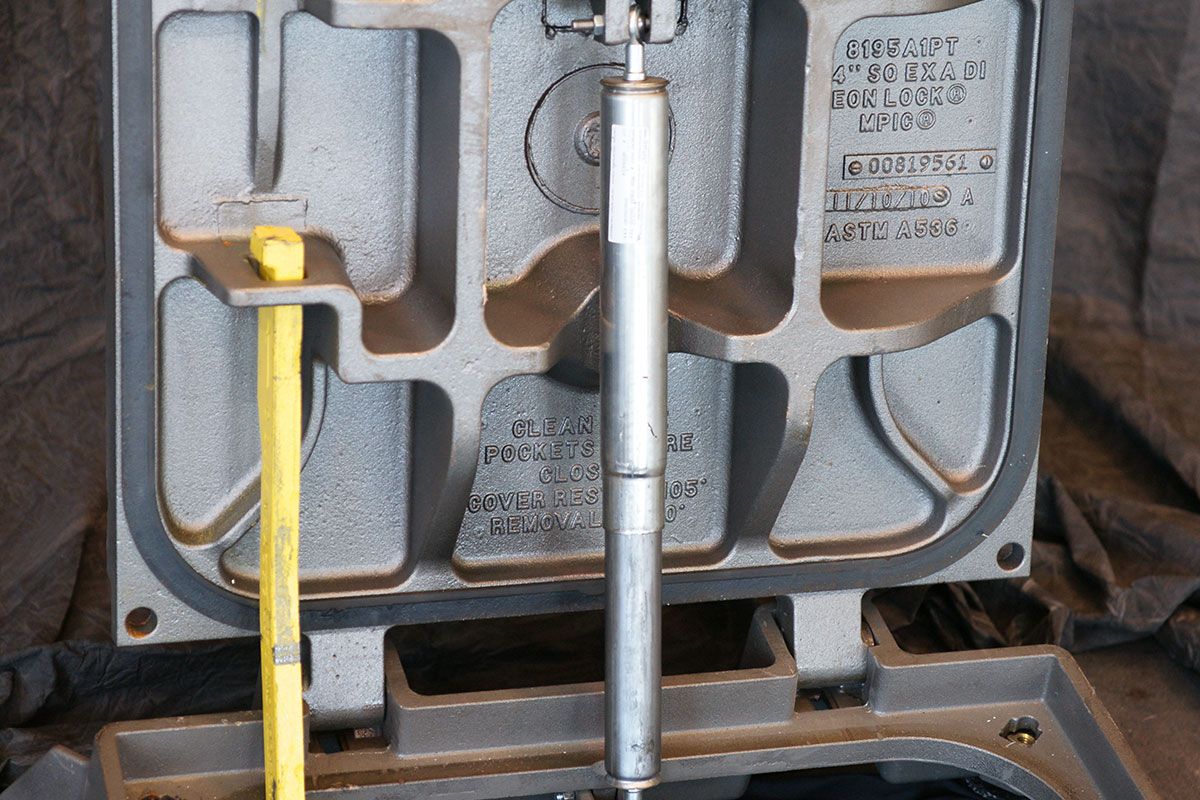

“We look at our products objectively,” offered Nathan Minnaar, a Product Development Supervisor who has worked at EJ for almost 11 years. “For example, some clients really need a full 36-inch clear opening, not just 36 inches minus the springs. Our hatch strut gives them a full 36 inches of open space.”

Global Expertise

The hatch installed at the Aeroporto de Lisboa marked the second extensive hatch project by EJ in Europe in recent years. This follows an installation recently completed at Manchester Airport in England. Both installations required EJ talent on each side of the Atlantic. Products were engineered and manufactured in the United States and installed by the Picardie, France team.

Additionally, a large number of these hatches were installed this past year at the King Abdulaziz International Airport in Jeddah, Saudi Arabia. Thousands are installed every year in North America at airports including JFK, O’Hare, Miami, LAX, SeaTac, and Anchorage to name a few.

Lifting Power

“With these hatches, you don’t need a team of people to go open a large hatch.”

The stainless steel mechanical struts that are used on the EJ Hinged Hatch line exemplifies the advantage new technology brings to EJ’s airport clients. Even with a 600-pound lid, the largest hatch cover by EJ - the 8198’s lifting mechanism requires only 35 pounds of lifting force, negating the need for a crane and promoting worker safety. Moreover, the 8198 still significantly exceeds FAA requirements.

“There just isn’t enough manpower to waste,” claimed Minnaar. “With these hatches, you don’t need a team of people to go open a large hatch.”

Safety and Reliability

"In a world where time is money, the hatch lift assist mechanism can be removed by releasing only two bolts."

In addition, the EJ hatches feature a safety bar that automatically locks the cover at 90 degrees when it is opened. Because of the hinge’s safety stop, a cover cannot close by itself. Closing the cover requires freeing the safety bar manually to unlock. A worker can do this from the side of the open hatch and need not place a limb or foot in the way, another feature that promotes safer working conditions.

“The strut improves safety whether the hatch is being opened or closed,” explained Minnaar. “The stainless steel spring inside of the strut assists when opening and slows the cover down when closing.”

EJ also devoted time researching the best mechanism for opening a hatch lid.

“Our research showed that stainless steel mechanical struts are more reliable than torsion springs.” added Minnaar. “Some of our older designs used coil springs and torsion springs, but we have found our lift assist struts to be greatly superior to those old spring designs. The old springs provided lift assist for only the first half of the opening process. The new struts are designed to assist for the entire range of operation. And in a world where time is money, the hatch lift assist mechanism can be removed by releasing only two bolts.”

“Beyond exceeding Federal Aviation Administration requirements,” Veldboom emphasized, “we consider the reality of who will be using a product and how it will be used.” With safety minded engineering and innovation, EJ provides reliable customer driven solutions in airports and ports around the world, by offering practical and reliable solutions for unforgiving environments where there is zero tolerance for error.