Manhole Covers Meet New Challenges

Unique product lines and solutions to answer ever changing needs

La información se presenta en Inglés. Una vez traducida, está se actualizará.

They are the descendants of mankind’s earliest efforts at city building, and although they are made of vastly different materials than the Romans used, manhole covers serve much the same purpose: separating the world’s citizens from the complex subsurface infrastructure below their feet.

During its 135-year history, EJ has manufactured tens of thousands of manhole covers at its United States foundries, so some of our oldest iron manhole covers are likely still in service—important devices, but invisible to the public they serve.

All manhole assemblies (the covers and the frames that surround them) meet three basic needs:

- They offer access to maintain the utilities essential for modern life.

- They protect the public from noise, fumes and gases, as well as heat, high voltage and explosions.

- They restrict and secure access to those vital supporters of modern life.

Manhole Designs Still Evolving

Manhole covers continue to evolve to meet new challenges. For example, to counter thieves who steal the covers to sell them for scrap, EJ manufactures manhole covers from composite materials: They have little resale value. Even so, to stop thieves from removing the covers, EJ offers manhole cover assemblies with a variety of locking mechanisms.

To reduce injury to workers who maintain underground infrastructure, EJ makes it easier to install, remove and replace the often-heavy covers. After all, EJ manufactures covers that weigh up to 500 pounds. EJ has conducted ergonomic studies on the best way to move the covers. They have taken those learnings and created real world features to help people work safer. We also offer written manuals, instructional videos and local support to our customers.

Worldwide Clients

By staying connected to our customers’ changing needs, EJ products continue to be specified in infrastructure projects in countries throughout the world and distributed in over 140 countries. Throughout the United States, hundreds of municipalities and Departments of Transportation have specified EJ manhole assemblies.

To meet these needs, EJ manufactures manhole covers in cast iron, ductile iron and composite materials, and we manufacture manhole covers to meet a variety of load-bearing requirements. These loads range from manhole assemblies for sidewalk foot traffic to assemblies for airport runways. Even the ubiquitous city street must be equipped with castings to carry the continuous weight of buses, trucks, cars and cranes.

Product Variety

The variety of EJ manhole assemblies and how they meet modern demands can be seen in the ERGO/ERGO-XL line. The ERGO line supplies security, safety and ease of use. As are all EJ castings, the ERGO products contain over 85 percent recycled content, which contributes toward achieving LEED credit.

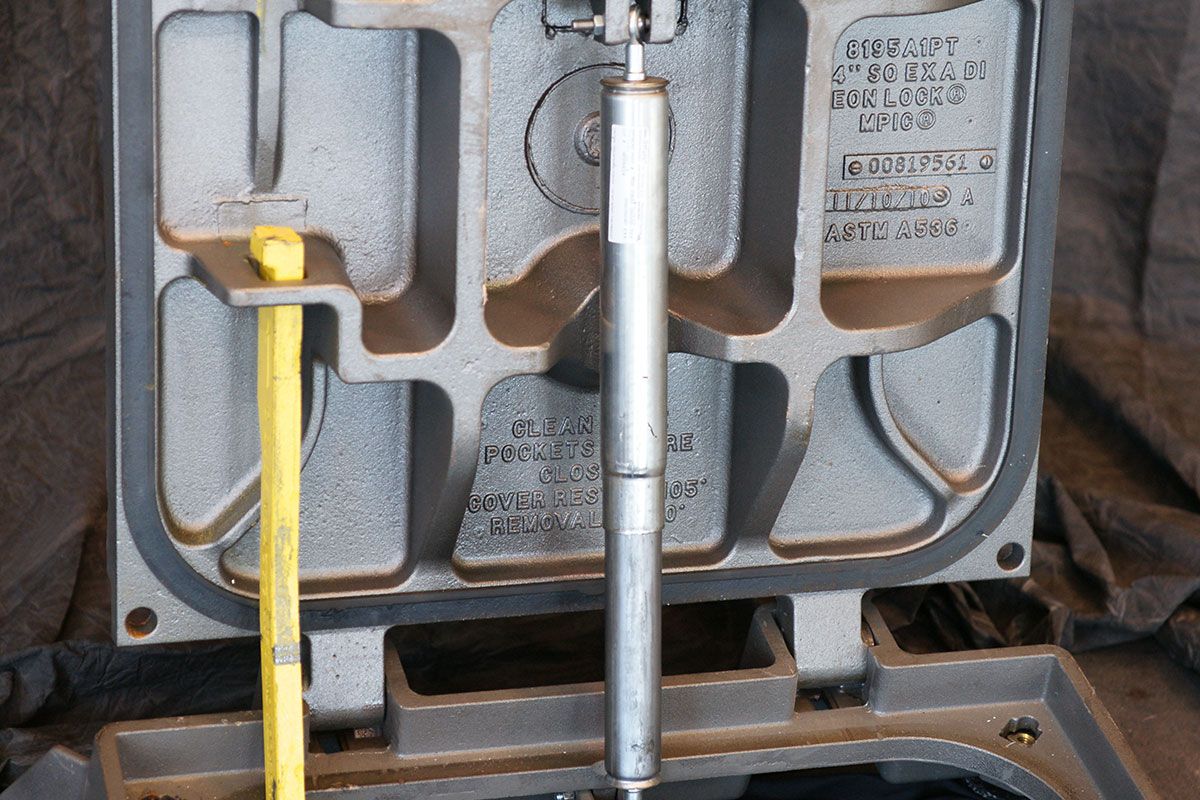

To address ease of use, the ERGO-XL offers a corrosion-resistant stainless steel mechanical strut that reduces the lifting force to raise the cover to less than 50 pounds. This maintenance-free strut symbolizes EJ’s understanding of customer needs. Made without internal gases or seals, the strut has an effective operating temperature of -30° F to 400° F and a tested durability of more than 150,000 cycles.

The patent-pending hinge design by EJ allows the cover to open up to 120 degrees. Here it rests in a safe and secure position and can be safely removed. In addition, the ERGO hinge design has a safety catch at 90 degrees to prevent accidental closing.

The security of underground infrastructure remains a top requirement for our customers, so EJ offers a variety of security systems on the ERGO product line. The Cam Lock security option improves security for frame and cover assemblies, while eliminating loose and missing fasteners. Because the cam lock wrench is only removable when the cover is locked, workers are assured it is engaged.

Custom-Made Products

If you cannot find the exact manhole and assembly you require, EJ produces custom products for unique applications. For example, the company routinely badges municipal and agency names on manhole covers. We have a team of engineers, the ability and expertise to create or modify a product to your specific situation and needs.

These modern devices, and our ability to create custom solutions to meet the needs of municipalities, are a far cry from the first manhole covers—pieces of stone or wood—used to allow access to trenches carrying sewage. The basic manhole cover remained unchanged through the 1850s, which meant that manhole covers coexisted with horses, when horsepower was the common means of city transportation. One researcher notes that those manhole covers had knobs to provide a gripping surface for horse hoofs, much like cover patterns today provide skid resistance for automobiles.

Integrating Government Regulations

While horse hoofs are no longer a concern, EJ products meet evolving government requirements. Because our manhole covers and manhole assemblies are manufactured in the United States, they meet Buy America provisions that require American-made products be used in transportation, state and local government projects that use federal transportation dollars.

Congress clarified the 1982 legislation by specifically stating that iron products are covered under the Buy America provision. The Department of Transportation's Buy America provision now reads U.S.—made "steel, iron, and manufactured products."

EJ products also meet the American Association of State Highway and Transportation Officials (AASHTO) standards and specifications for all five transportation modes

- Air

- Highways

- Public transportation

- Rail

- Water

Helping Customers Meet LEED Standards

LEED® (Leadership in Energy and Environmental Design), an internationally recognized green building certification system, provides third-party verification that a building or community was designed and built using strategies aimed at improving environmental quality across crucial metrics.

The sales team at EJ routinely assists customers in qualifying for LEED® credits on new projects. The LEED® Green Building Rating System is the nationally accepted benchmark for the design, construction and operation of high-performance green buildings.

EJ Products Help Customers with LEED Standards

A majority of EJ products can help our clients qualify for LEED credits under the Materials and Resources category. Alternatively, credits may be earned through the Sustainable Sites category and the Storm Water Design section. Further opportunities for earning credits exist elsewhere within the ratings framework.

A majority of EJ products can help our clients qualify for LEED credits under the Materials and Resources category. Alternatively, credits may be earned through the Sustainable Sites category and the Storm Water Design section. Further opportunities for earning credits exist elsewhere within the ratings framework.

EJ castings, manufactured entirely in the United States from gray iron, conform to American Society for Testing and Materials (ASTM) A48. For ductile iron, it conforms to ASTM A536. The material used to produce the castings has a minimum recycled content of 85 percent. Approximately 20 percent post-consumer and 80 percent post-industrial materials comprise that 85 percent recycled content.

Innovation to Meet Customer Needs

Of course, meeting customer needs also means meeting the needs of our clients’ customers’ EJ innovates to meet those needs, even if those needs have existed for some time. This was the case in Kansas City, Missouri.

As engineers, city and traffic planners, and elected officials know all too well, traditionally designed manhole covers can contribute to bumpy streets, degrading the quality of city life for pedestrians, cyclists and vehicle occupants. In response to that challenge, the SELFLEVEL® Access Assembly features easy installation and provides infrastructure protection that remains aligned with the finished road surface during use.

As pavement degrades or construction changes it, traditional design castings may rest significantly higher or lower than the surrounding street surface. Factors can include

- Heaving/uplift due to ground frost

- Settling of the entire manhole structure

- Site deterioration

- Cracking of concrete or asphalt

- Inclined street surfaces

The SELFLEVEL® addresses these challenges by including a below-ground guide frame with an upper frame that allows for movement in position, so that a cover or grate will “float” or remain level with the surface.

The SELFLEVEL® responds well to heavy traffic, while meeting AASHTO loading specifications. Many are located in Kansas City bus lanes, with no failures reported. Cost benefits are based not only on road life and pavement integrity, but also on labor and materials for a minimum of one-to-three manhole adjustments with future pavement overlays/restoration.

In Kansas City, the SELFLEVEL® is viewed as meeting two key criteria of its Smooth Streets Initiative:

- It provides a solution for the effects of heavyweight vehicles in traffic.

- It adjusts to varying pavement slope resulting from the crown of the road.

We complement our extensive in-house knowledge with third-party research and input from industry experts. We also ensure that our products perform optimally through finite element analysis (FEA), in-house tests on materials, and load tests on product prototypes.