When Off-the-shelf Infrastructure Solutions Aren't Enough

Communication, collaboration, and experience combine to create a best-in-class solution for one major utility provider

A major utility needed a best-in-class solution to replace damaged, non-standard access hatches.

La información se presenta en Inglés. Una vez traducida, está se actualizará.

"When I heard the big utility guys were tracking me down to help solve their field problems, I figured I must have done something right!" says Gerald Davis, the fabrication manager at Fineline Metal Fabricators in Terrell, Texas. "I had worked with this particular electric power company for 12 years at another fabrication shop and enjoyed my work, but that 85-mile drive to work finally got to me so I left to take a job closer to home. It was then I learned I was being recruited to help with utility upgrades."

"That's true," says EJ Technical Sales Specialist in Ardmore, Oklahoma, Tim Powell, who has worked with Davis since 2013. "Gerald is absolutely the go-to-guy for any field problems that arise. He has years of troubleshooting experience."

Davis worked closely with the company network design group and used critical input from knowledgeable field technicians and utility engineers for the many "tweaks" that led to the best access solution for their site-specific needs.

EJ Orchestrates Five Design Iterations for Utility

But "tweaking" is an understatement of the complexity and design evolution of this challenging project. "EJ had never produced a self-supporting aluminum hatch" says Powell, "Let alone one that provided all the specific loading, safety and ergonomic functions demanded by the utility." In their own words, this narrative describes how the project principals worked their way through five design iterations to finally solve the utility's specific needs. This story also reveals the foundation for EJ's success: EJ professionals who deliver exceptional engineering ingenuity and dedication to owner satisfaction — not to mention their tenacity and perseverance!

"The utility wanted one code-compliant hatch solution that would be robust enough to support vehicular traffic at various entrance configurations in their service area." - Tim Powell

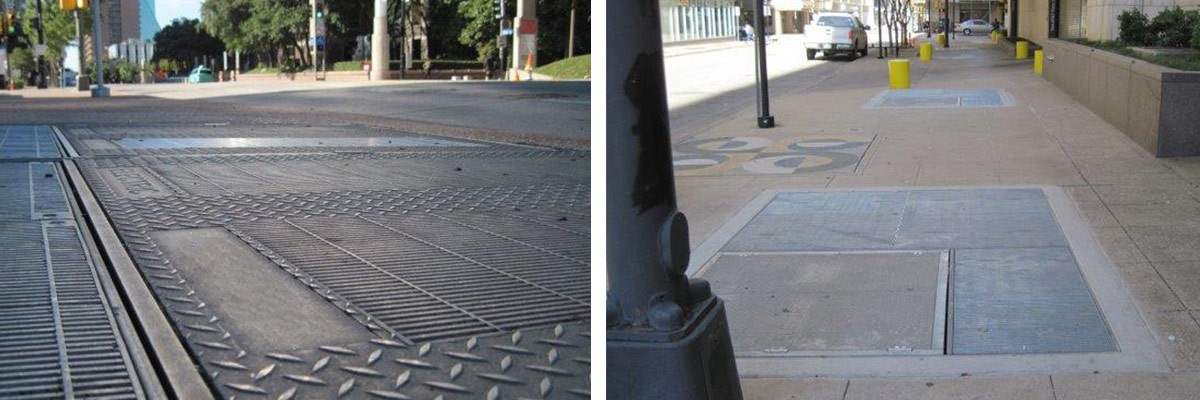

Sidewalk Sweepers Wreak Havoc

"In this major metropolitan area, the older 1970s-vintage entrances to underground stations were not designed to support heavy maintenance trucks," says Powell. "In particular, the damage caused by sidewalk cleaning machines just tore up the ventilation grating at many vault access points." Over the years, changing technology led to greater use of heavy delivery and service trucks on sidewalks that were designed for much lighter traffic. "Besides the need to replace deteriorated hardware," says Powell, "The utility wanted one code-compliant hatch solution that would be robust enough to support vehicular traffic at various entrance configurations in their service area. Many of the vaults that supply power to the major office buildings in this area are quite deep, and safety — of both the public and system maintenance personnel — is the non-negotiable requirement of any hatch design under consideration."

Feeling the Heat

"Hatches for the utility's underground network vaults must be designed with grating to vent heat — often considerable heat — from electrical transformers and equipment," explains Tim McKernan, EJ Facility Manager in Cicero, NY. "Fans are used to cool the underground air and the open spaces in hatch grating, and allows fresh air to pass through to keep vault conditions at safe temperatures for utility technicians who must climb down into them for maintenance or installations. As transformers are changed out to higher capacity units, heat becomes a greater concern and hatches must be fully vented."

Tamper-Proof Security is Growing Concern

"Two points of securement are required for a hatch assembly to deter vandals: the hatch barrier has an initial padlock and then a second recessed padlock clip that secures the safety grating," says McKernan."The idea here is that we create a 'delay and detect' opportunity to increase security."

With growing Homeland Security concerns over potential vandalism and/or terrorism attacks on the US power grid, utility infrastructure engineers are looking for much more secure access assemblies that include lock-out redundancy.

New Standards for a Modern World

"Today, major power industry renovations are common — many of our nation's utilities have very old infrastructure," says McKernan. "This includes dated access equipment not rated for potential loading, non-compliance with current AASHTO load ratings, and surface designs that do not meet today's ADA's 'high-heel' proof or bicycle safe standards. For example, for a hatch grating to be high-heel proof, the grating openings must be ≤ ¼ inch."

"Beyond ADA requirements, this modular hybrid access hatch with a SAFE HATCH® Safety Grate by EJ meets OSHA standards [1920.23] for confined space openings in walls and floors. OSHA now requires permits for all confined spaces where sewer gases (methane) can permeate underground vaults and prove fatal."

"Everyone understands that public safety is paramount to utilities, and pedestrian safety depends on the slip-resistance or coefficient of friction [µ] of hatch assembly surfaces." McKernan says that while "other manufacturers may meet minimum ADA standards of µ = 0.6, EJ uses µ = 0.9 to ensure public safety based on its extensive worldwide experience."

Solution: A Modular Hybrid Access Hatch with the SAFE HATCH® Safety Grate System by EJ

"We came up with a modular hybrid design that can be used just about anywhere in the service area," says Powell. "Network design engineers were looking for a design that would function in different configurations and had to accommodate various ladder mountings, so we made a hatch assembly that can be rotated 360º as needed."

Davis explains some of the design process: "The existing steel access doors were very heavy. At first, design engineers at EJ wanted to use stock aluminum hatch doors that were lightweight, low maintenance, and easy to open and close — but aluminum assemblies alone could not support heavy traffic loading — unless they were surrounded by concrete."

"To solve this problem, we designed a 6 in. steel C-Channel to support an aluminum door large enough for easy personnel entry, and that also provides AASHTO H20 rating. It’s the flexibility of the frame dimensions that solves the custom sizing required for three opening configurations [ranging ≈ 5 ft x 7 ft to 12 ft x 7 ft], and it is the design's modularity that provides installation speed. It only takes about 30 minutes to remove doors and grating when switching out a transformer."

When asked to name his biggest challenge in providing the final hatch solution, Davis's response was surprising — it wasn't in the technical details. With so many sources of design input and tweaks, "It was keeping everyone on the same page throughout the design process!"

Final Analysis: EJ Attention to Client Service

EJ and Fineline began this project knowing that the client was already familiar with a less-expensive access hatch that was available for their retrofitting projects. The real challenge, therefore, was to design an access hatch assembly that was far superior to the competition — specifically a superior solution for public and personnel safety, ease of use, and adaptability for the variously configured sites across the service area.

In the end, it was the EJ access hatch lift assist and safety grates that sold the field technicians, but it was the direct support and informed technical assistance from EJ, with every tweak and design update, that sealed the deal for the utility's transmission distribution engineers. EJ means more than a system that works better than the competitors - EJ means total service commitment and a determination to ensure the customer is completely satisfied.

Learn More

Talk to an expert at EJ to find out how the innovative solutions by EJ can work for your next project. Contact us today or schedule a Lunch and Learn.