Better Covers for Peach Bottom

EJ rehabilitates access panels and manholes at nuclear power plant

Manhole covers, utility vaults, and access points can seem like a small detail, literally underfoot and easy to ignore. But when they're done right they make a big difference.

Cette information est présentement disponible en anglais. Une traduction suivra sous peu.

Peach Bottom Atomic Power Station, near Harrisburg Pennsylvania on the Susquehanna River, is one of the oldest nuclear facilities in the United States. The 2011 Tōhoku earthquake and tsunami, which caused meltdowns in three Fukushima reactors, was an eye opener for Peach Bottom.

"Nuclear plants all over the world reinvestigated their backup systems," explains EJ Facilities Manager Tim McKernan. "At Peach Bottom, the plant operators took a proactive approach to upgrade more than a hundred sewer manholes and utility access hatches. Many needed varying degrees of attention. Some weren't properly labeled, others weren't skid or water resistant, or weren't rated for high enough loads, and many were just hard to open."

MAJOR CHALLENGES

Existing regulations imposed a major challenge on the retrofit—practically speaking, existing concrete openings could not be modified. Fortunately, EJ, one of the world’s largest manufacturers of manhole covers and access hatches, had a deep inventory of specialized solutions to draw on; "Honestly," says McKernan, "I think we’re the only firm that could have solved every unique challenge at this plant."

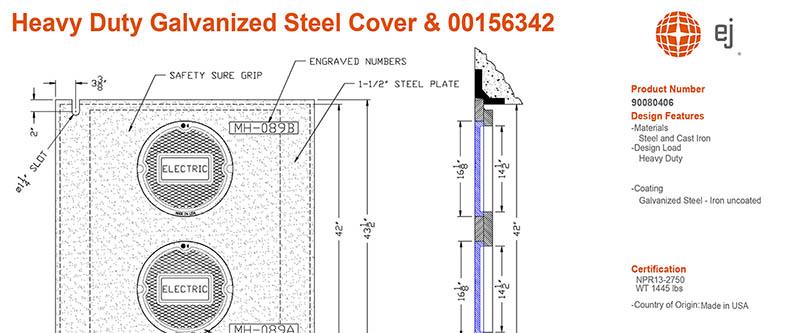

The replacement of one large electrical access panel is a good example of the problems EJ faced. To support forklift traffic, the original panel was made of two heavy cast iron rectangles; "And rectangles are a bad shape," McKernan points out. "Unlike circular covers, they can slip and fall into openings. Given the weight, and the plant's confined space policies, that would have been a disaster."

Because this panel needed to be accessed frequently, plant operators had established a written procedure for an opening that required at least three employees to lever open the hatch and prop it with a specially cut and labeled length of 4"x4" lumber. "Opening this panel was a feat, to say the least," says McKernan.

Because this panel needed to be accessed frequently, plant operators had established a written procedure for an opening that required at least three employees to lever open the hatch and prop it with a specially cut and labeled length of 4"x4" lumber. "Opening this panel was a feat, to say the least," says McKernan.

AN INNOVATIVE SOLUTION

EJ proposed a single large panel made of 1-1/2" thick steel plate, inset with two round cast iron covers. The steel plate stays in place, and a single employee with a manhole pick can remove either cover. This panel design was already designed for AASHTO H-20 loading (40,000 lb proof load on 9"x9" area), and featured a non-slip surface and proper labeling. It's clearly a safer and more convenient solution, and Peach Bottom operations staff were happy to get rid of the 'special' 4"x4".

Many of the heaviest covers were replaced with ergonomic covers featuring lift assist spring struts and self-engaging safety bars.

Several access locations required attachment points for new sensors. "That was a new one for us," McKernan says. "To detect water infiltration automatically, new ultrasonic transducers and antennas were being installed, which meant we had to come up with attachment points that placed them where they wouldn’t obstruct openings or interfere with normal use. And the transducers had to have line of sight to water collection areas." To meet this challenge, EJ designed an adjustable rail system to work with varying dimensions. Finally, many of the heaviest covers were replaced with ergonomic covers featuring lift assist spring struts and self-engaging safety bars.

Manholes, utility vaults, and access points can seem like a small detail, literally underfoot and easy to ignore, but when they're done right they make a big difference. McKernan says, "The Peach Bottom employees are so impressed with the convenience of the new covers, I hear they sometimes walk around just admiring them."

LEARN MORE

Talk to an expert to find out how the innovative solutions by EJ can work for your next project.