Engineered Solutions

Providing ergonomic and safe access to pump chambers

|

Installation Area

|

Overview Large span chamber openings on water networks can mean difficult to lift & manoeuvre manhole covers which can render assets inaccessible and unsafe for operations and maintenance teams. During a site survey on a pump station with 3 separate chambers, EJ found that the in situ covers prevented ease of access to underground equipment. The process of opening and closing these covers was costly, labour intensive and time consuming as a hired lift and additional manpower was required on site. When fully opened, the area was unsafe with no edge protection around the chamber opening and no fall protection to prevent a serious accident.

Original chamber covers with no fall or edge protection |

|||||

|

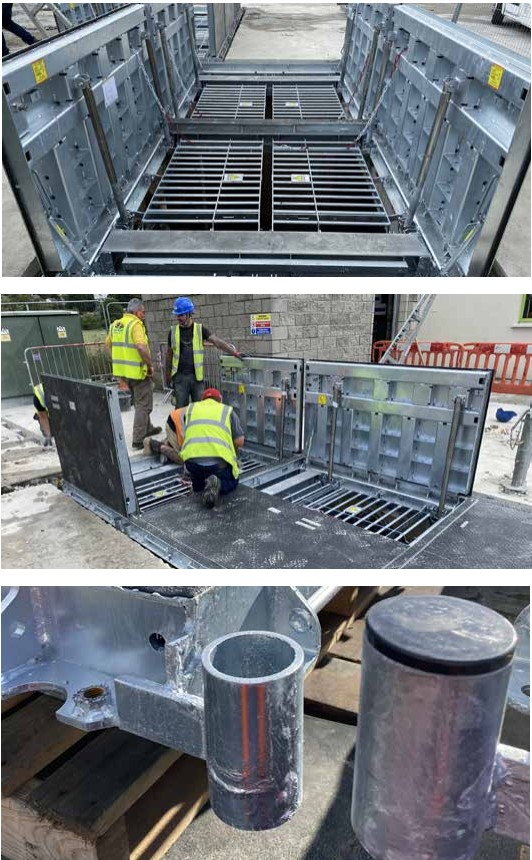

A risk adverse approach Through engagement with the client representatives, bespoke fabricated steel access covers were designed in 2, 4 and 6 parts depending on clear opening sizes. Each were fitted with mechanical strut lift assistance that ensured safe and easy access to the network. Compliance to industry standards for long term performance

Speedy Installation less than 1 hour per cover Collaboration with EJ at the design stage enabled a risk adverse outcome for the client and project teams. User safety was critical to the design with ergonomics and fall protection the priority. Installing 3rd party certified steel solutions ensured compliance to the relevant standards and client specifications, guaranteeing long term performance. |

Handrail sockets for edge protection poles |

|||||

|

For more information on our engineered access solutions, please contact our Business Development team. |

||||||