Back to the Future for Dam fine Results

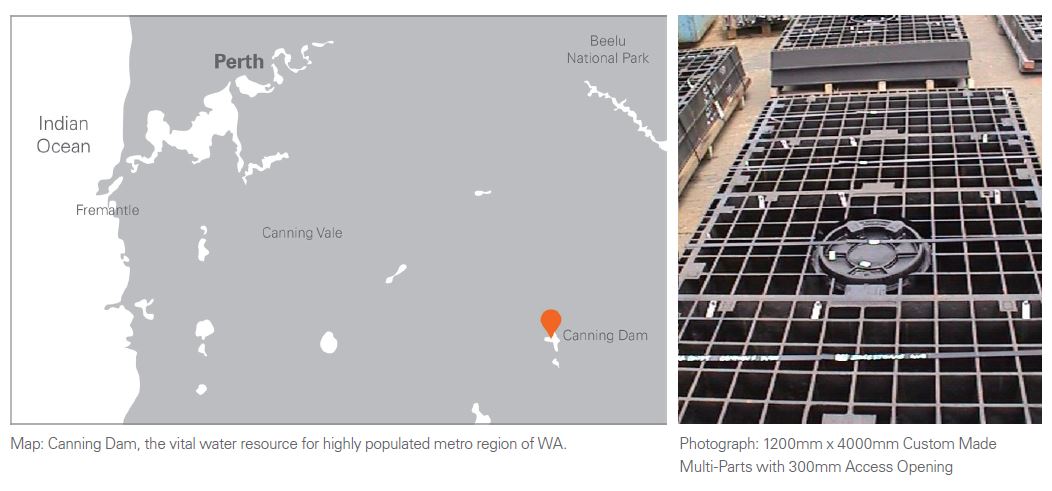

Canning Dam Western Australian Water Authority

Drinking in Surety of Supply

The world’s most important commodity is water. It is life itself, especially in the harsh, dusty, dry lands of the Australian continent. In Western Australia in the 1990s, the demands placed on dammed water increased exponentially, so the State’s major water-containment facility, the Canning Dam, needed an upgrade to increase its capacity.

To increase catchment and capacity meant raising the dam wall itself. Integral to this achieving this, was some specialist engineering which involved extending steel rods already in place in the existing wall, into the new wall structure. Once in place, regular maintenance inspections were – and still are – carried out.

For this purpose, very specific access covers were required including a smaller 300mm diameter size which obviated the need for the much larger (1200x4000), more cumbersome covers to be lifted and accessed.

"Products are easier to sell when you have the credentials of a century plus of experience behind you, such as it is with EJ". Ian Maddocks, HaveStock Factory Foreman at the time of this project, now National Sales Manager of EJ.

The Inventive Solution by HaveStock (now EJ)

Since this Western Australia Water Authority’s project was of a very particular nature, it required the services of an innovative supplier, and HaveStock (now EJ) was first port of call. The specifications called for a range of Class D (210kN) 1200mm wide covers. These were not off-the-shelf specifications at all, so they had to be designed and constructed from scratch.

Manufacturing and transporting from Brisbane to Perth was not a cost effective solution, even if the parts were multi-parts in a smaller size with specially engineered support beams. The one very clever solution came from inspiring Brisbane HaveStock founder, Tim Bottomley, who ingeniously designed a new, larger width cover that would take the loads of heavy traffic.

He committed funds to the design, FEA (Finite Element Analysis), pattern making and ultimate casting. Then, to guarantee the feasibility of his design, he flew cast prototypes to Brisbane for load testing at the then QUT School of Civil Engineering. Once quality checked, production flowed and parts were assembled as if they were oversized 6-part trench covers, complete with 300mm inspection openings.

EJ Dedicated 'Infrastructure' Team for Asia Pacific

Our dedicated team is available throughout Australia and the Pacific region to assist local authorities, consultants and contractors during the specification, construction and operation phases. EJ is proud of its 135 years of international experience and expertise across the ever-growing infrastructure sector.

EJ offers an extensive range of globally manufactured product that guarantees the highest quality to meet the unique demands of complex infrastructure projects.

Client:

Western Australian Water Authority

Location:

Canning Dam, WA

Products:

Custom Design, Cast, Assembled & Delivered

1200mmx4000mm Multi-Part Covers with 300mm Access Opening