Quality and Design

Delivering the Best Products

Optimized Manhole Design

When it comes to making use of modern iron casting design and manufacturing, EJ has invested time and energy into delivering safe, high quality products through innovation.

EJ uses advanced technology to produce products that aren’t ‘overbuilt’. Engineers focus on high caliber design and consistent material quality. The result: covers, frames, grates and hatches that are stronger, lighter and optimized for real world performance. Less fuel and raw material is consumed, making EJ products safer, easier and more ergonomic to use.

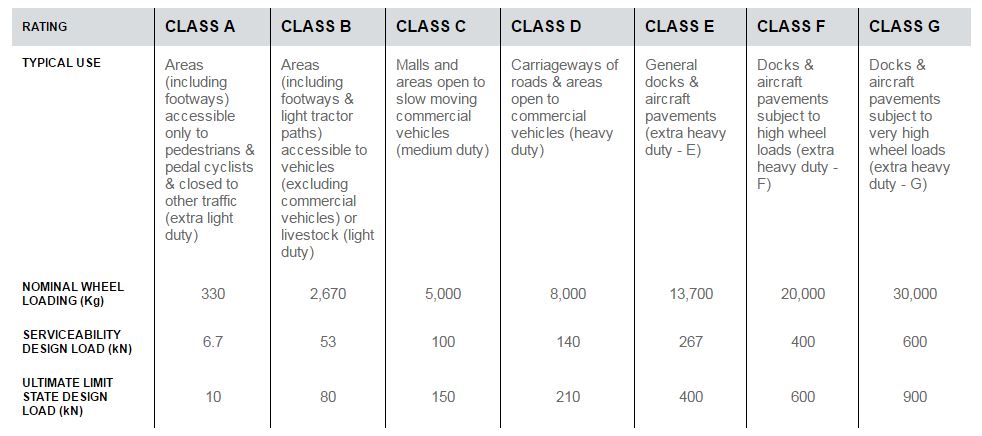

Ratings on EJ products exceed AS3996 Australian Standard Load Classification requirements and remain compatible with existing specifications in your city’s network.

Features include:

- Stackable frames are and safer to store, transport, and handle, offering improved worker safety and efficiency.

- Ductile iron covers feature a modern ribbed design that make them lighter, stronger, and longer lasting.

- High precision casting process ensures greater consistency and tighter fitting street and access infrastructure products.

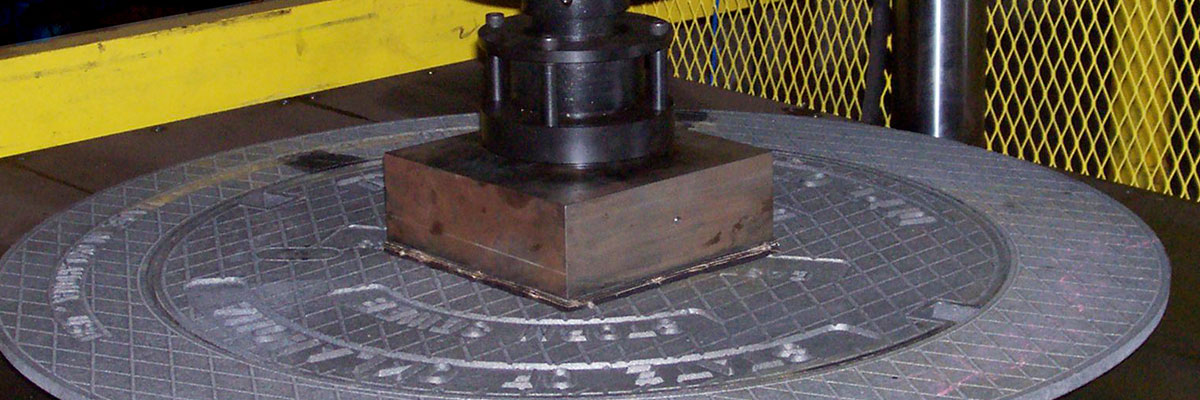

Proof Load Testing

To be rated for heavy duty traffic, construction castings must pass proof load tests. Specifically, the testing procedure consists of the application of 40,000 pounds of force—that’s about ten minivans—to a 9”x9” contact area, for one minute, in the center of the cover or grate. The casting is then inspected and rejected if any cracks or deformations are found. EJ takes this test very seriously, and our castings are typically tested far beyond this specified proof load. To maximum strengths, we test to destruction. This rigorous testing protocol is your assurance that EJ covers and grates will stand up to all expected traffic conditions.